Even though reinstalling instruments is way, way down the line, I was thinking about what to do. I wasn't a big fan of the Raymarine fishfinder that someone installed on a super classy dashboard mount that used to jut from the cabin trunk, but I dug out the manual (thank goodness for a previous owner who kept everything) and discovered that it actually has some decent functions AND it can be flush mounted. Cool. I cleaned it up and took it out to the boat to see if it worked.

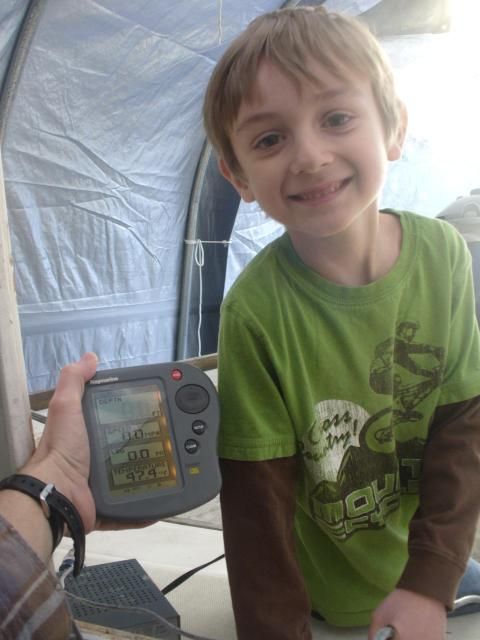

My younger son, always eager to help.

It does! And it's actually pretty cool. I don't like the fish finder screen much, but this data screen is perfect for sailing, showing depth, speed, log, and water temp. My eldest son (not pictured) spun the paddlewheel while I watched the screen for a reading. Amazingly, we hit nearly 6 kts in the driveway. So, it looks like this unit will be flush mounted on the rear of the cabin trunk when the time comes to put things back together. This little unit will save over $300, the cost of a relatively inexpensive Raymarine ST40 Bidata.

While I was feeling handy and seeing what I could do to make "old" instruments serviceable, I brought the compass in and cleaned it up. A large bubble had formed in the globe, and I just happened to have some Ritchie compass fluid on hand from servicing Ariel's compass a few years ago, so I took the thing apart, improvised a filler using a turkey syringe and part of a foam earplug, and refilled the fluid.

It worked! And the two lights work as well.

I also finished what I hope will be the final round of major sanding/grinding. Using a combination of angle grinder w/ flapper wheel and a 6" sander, I think I'm ready to call that part of the project DONE!